RCD Test

RCDs (residual current devices), or safety switches as they are commonly called, are important electrical safety devices that can save lives.

Over time the reaction time of most RCDs can slow down or stop functioning due to normal wear and tear. Without regular testing you would never know if this was the situation. As a result people would be exposed to the consequenses of electric shock incidents.

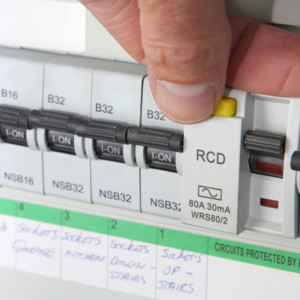

Most commonly you will find RCDs in the main switchboard of workplaces and homes. Many appliances, such as powerboards, can have an RCD incorporated into their design which must also be tested as part of the overall appliance inspection and testing procedure. Both the appliance and the RCD must pass to achieve an overall PASS, noting it either fails then an overall FAIL must be applied.

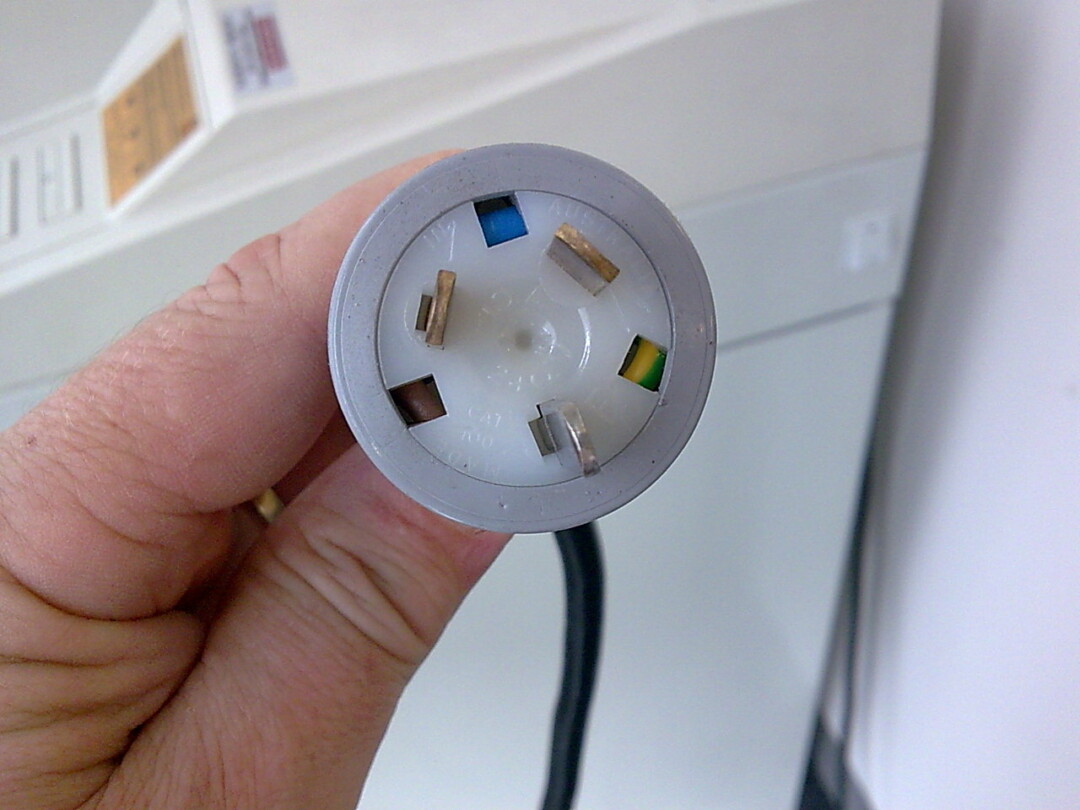

Example of a PSOA with an RCD incorpated into the design. This device would require inspection and testing using the process for a powerboard and then checking the trip time of the RCD. Both would require a PASS before returning to service.

It is important test and tag technicians include RCDs in the test and tag program and know how to correctly inspect and test them.

RCD Test Methods

There are two ways to test an RCD;

- Push Button Test

This is a simple test that can be performed before using a portable RCD or appliances, or when incorporated into appliances such as some leads and powerboards etc. The test involves quickly pressing the RESET button and noting if the RCD trips “without undue delay“.

It is important to note this is not a particularly accurate test and should not be used to determine a pass or fail outcome when testing and tagging the device however it does provide the user an indication the RCD is working. - Trip time test

This is a more accurate method that requires the use of test equipment that can simulate a fault and measure the trip time to within 1 mS ( 1/1,000th of a second).

To learn how to correctly inspect and test RCDs, see our RCD Course