Failed Appliance Frustration

- Have the appliance repaired

- Discard the appliance

- Use the appliance for parts

- Do nothing further with it

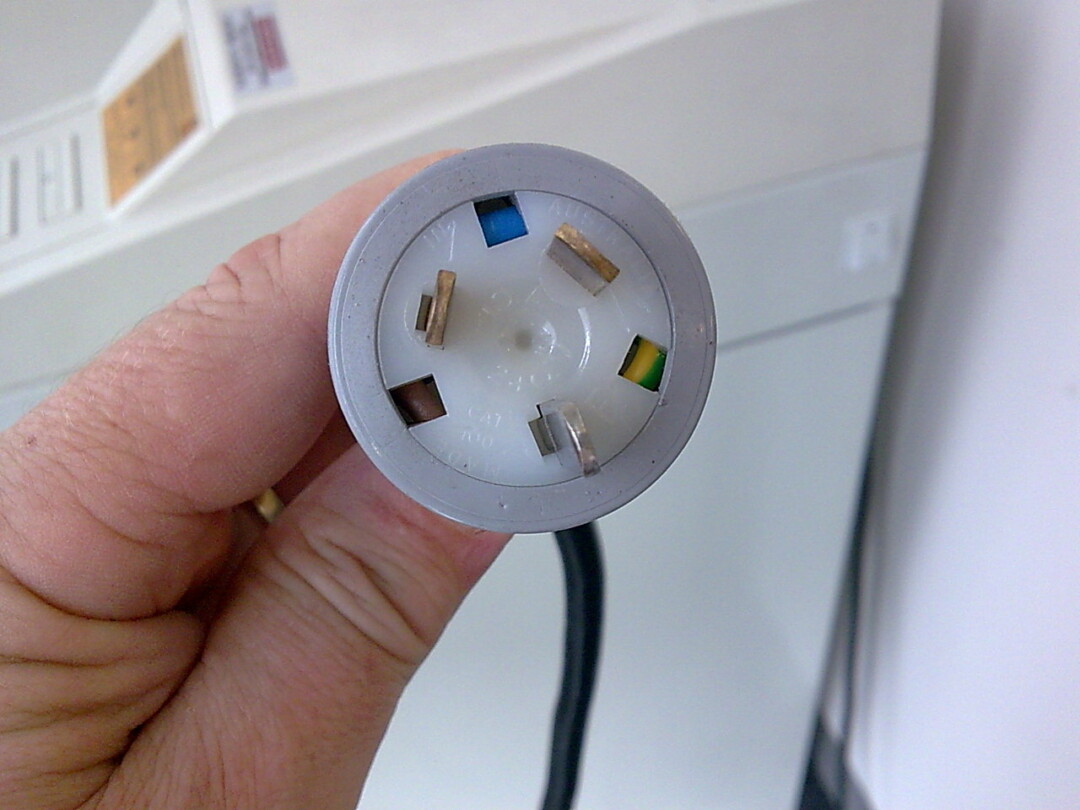

Lead that had been failed and removed from service in previous visit put back into service despite “danger tag” being clearly visible.

I’m often asked about what obligation does the technician have to ensure it isn’t used again until the defect has been rectified and the appliance has been tested and tagged again and passed. My answer is fairly simple; as test and tag technicians our role is to report, not to enforce. What I mean by this we report the outcomes of the inspection and testing process by way of attaching tags and keeping records of the outcomes. We are not required (or empowered) to stop people using failed appliances.

In the image to the right you can see an extension lead that has a FAIL tag attached and clearly visible yet it is in use. A defect had been detected in the lead during the previous visit and it had been removed from service. At some point of time the lead had been returned to service without the defect being rectified. This is an obvious OHS breach initiated by the person(s) who plugged it back in. As part of our duty of care obligation we removed the lead from service, again, and brought it to the attention of the OHS Manager at that work place.

Unfortunately this was not an isolated case. I can recall many instances where I have failed an appliance and within minutes of doing so observed it being used. When I tell them they shouldn’t be using it a common response is “I don’t have a replacement and need to use it”. Again, there’s not much I can do apart from explain the dangers to them and then report it to the OHS representative. To some that might sound like “dobbing someone in” but consider this. If the user were to get an electric shock from a failed appliance and you saw them using it again, the courts might hold you partially or fully responsible under OHS laws because you failed your duty of care obligations.